To fulfill a commitment in satisfying Customers with High Quality Results, POLARIS constantly seeks for new & better solutions in every project. Among of which is the capability to offer a "COMPLETE PACKAGE" for Plastic Injection Molds. This option provides Customers more confidence with the development of a project.

OUR SERVICES

We take in satisfying the needs of our customer. Our technical staff assures that we provide a good design and easy to maintain mold also provide time-table bar chart for easy mold fabrication development monitoring.

For the convenience and satisfaction of our customer, we assure a good after service policy.

We, maintain and balance Q.C.D.S. policy;

Q – Quality

C – Cost

D – Delivery

S – Service

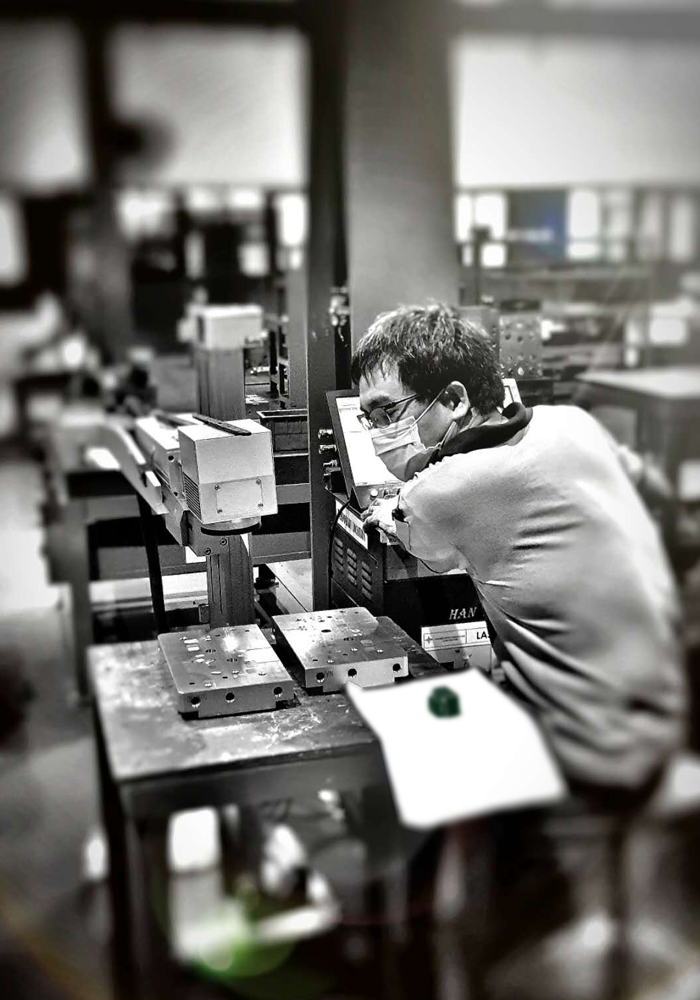

MOLD FABRICATION

INJECTION TRIAL

INJECTION MASS PRO

WE ARE SPECIALIST IN : WHAT WE DO

PRODUCTION MACHINES AND SOFTWARE

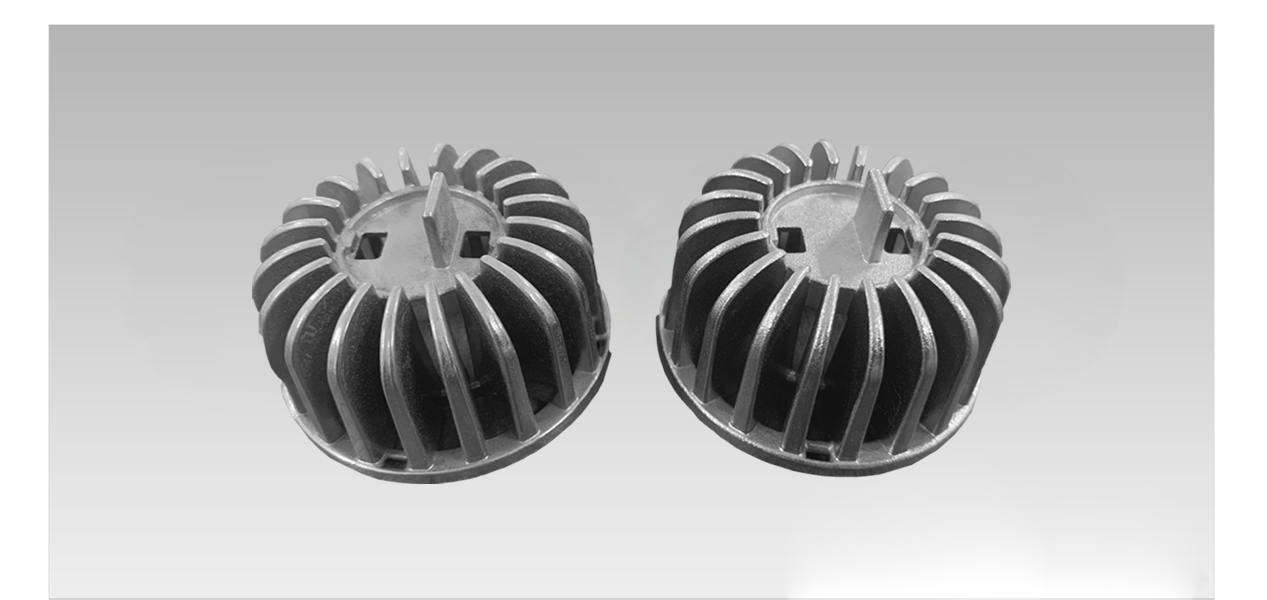

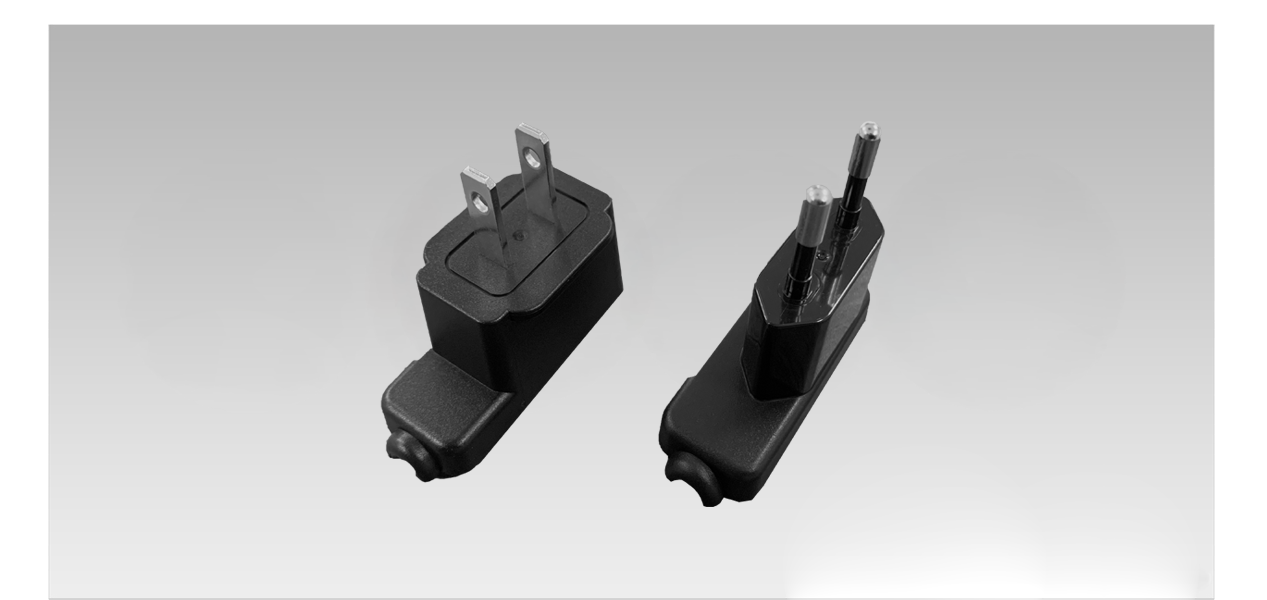

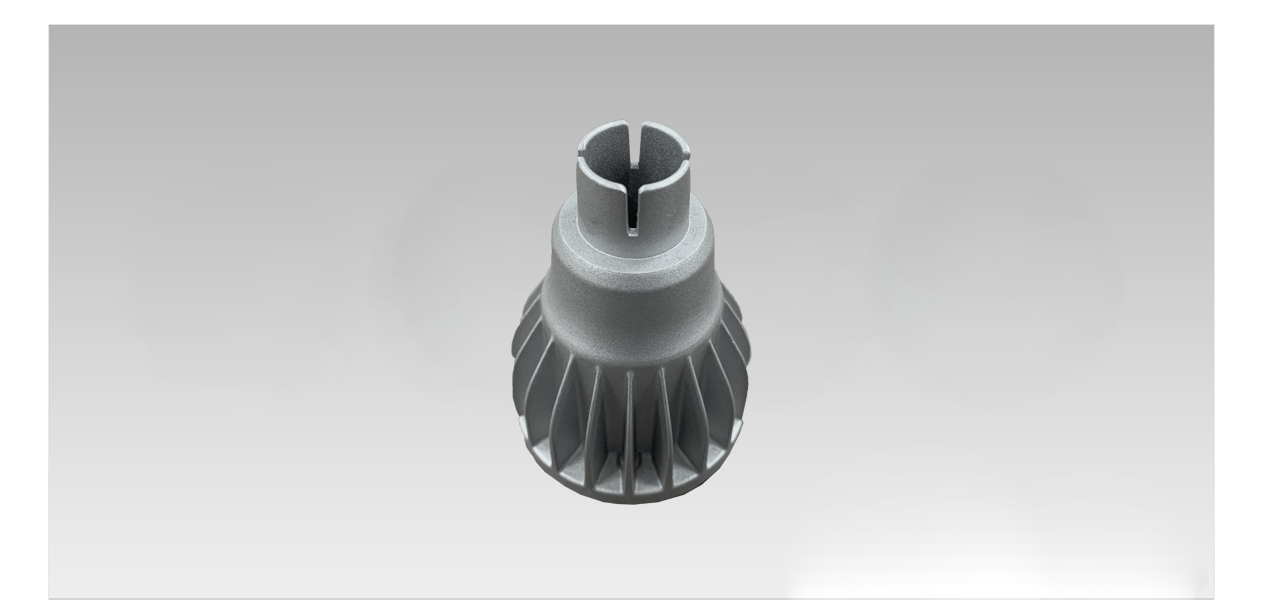

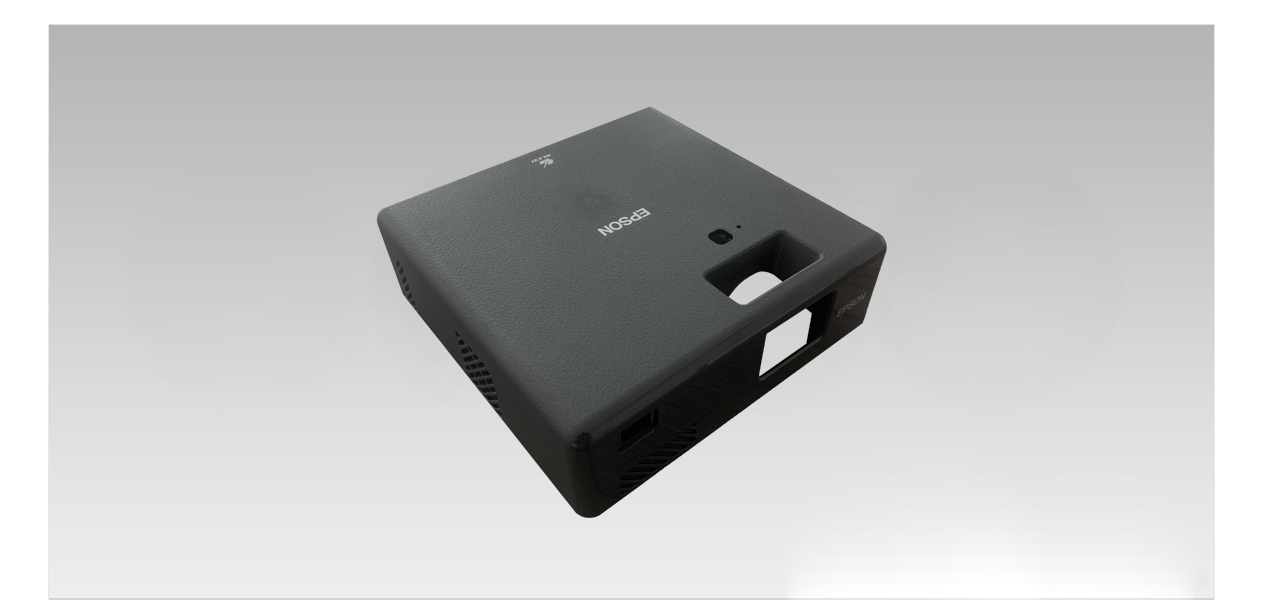

PLASTIC INJECTION

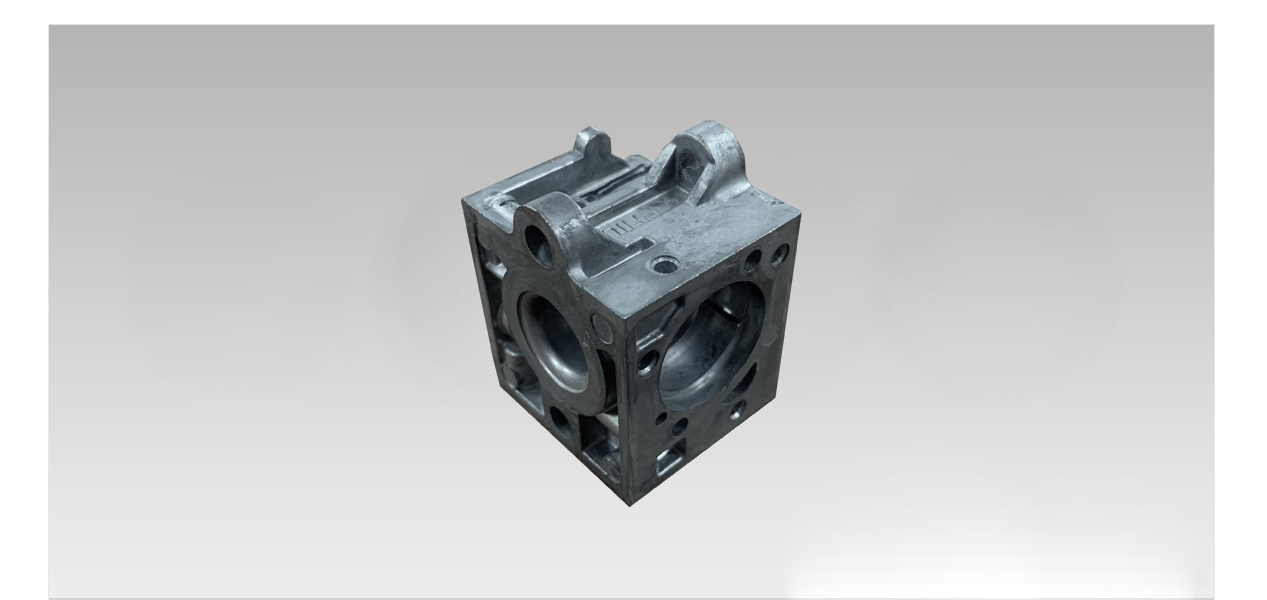

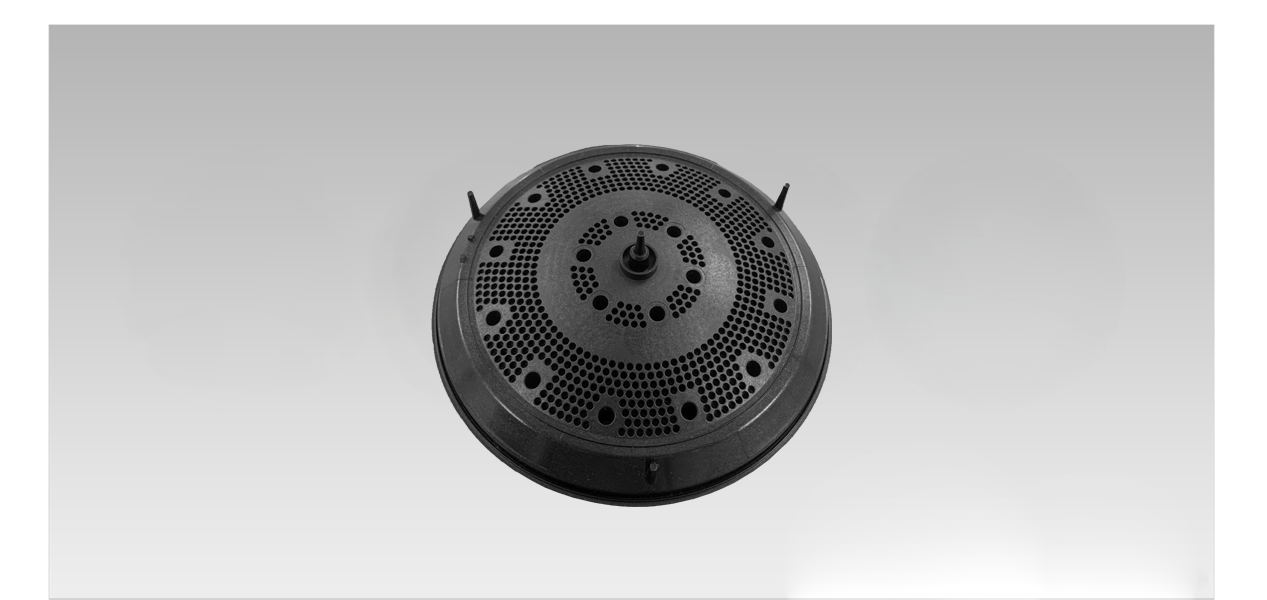

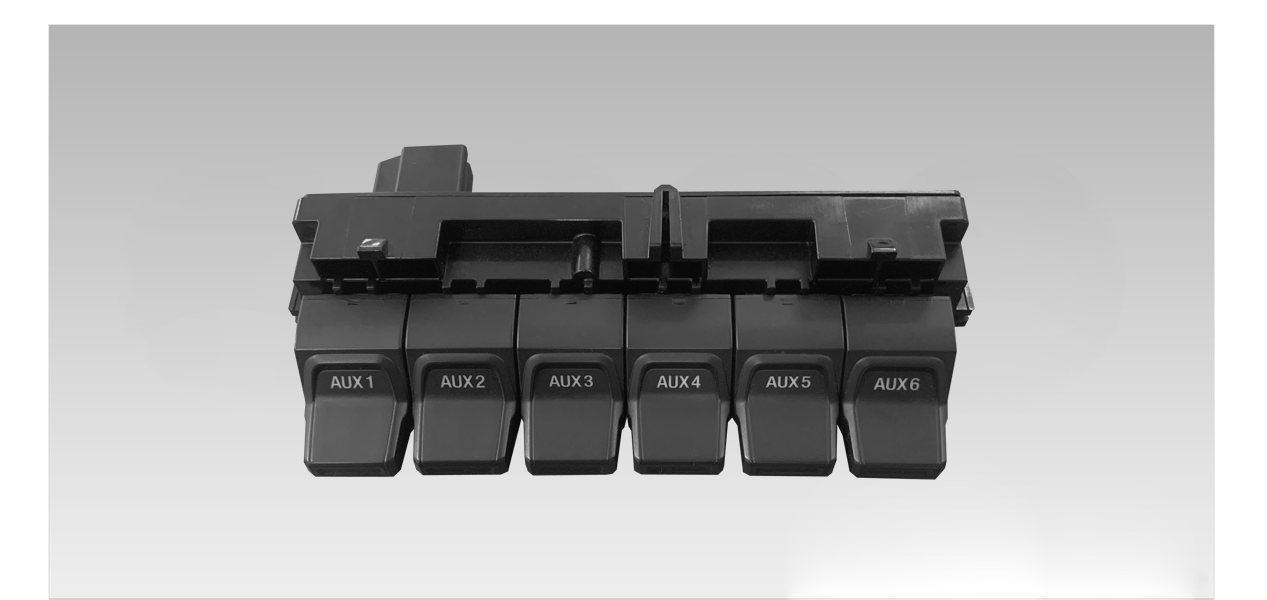

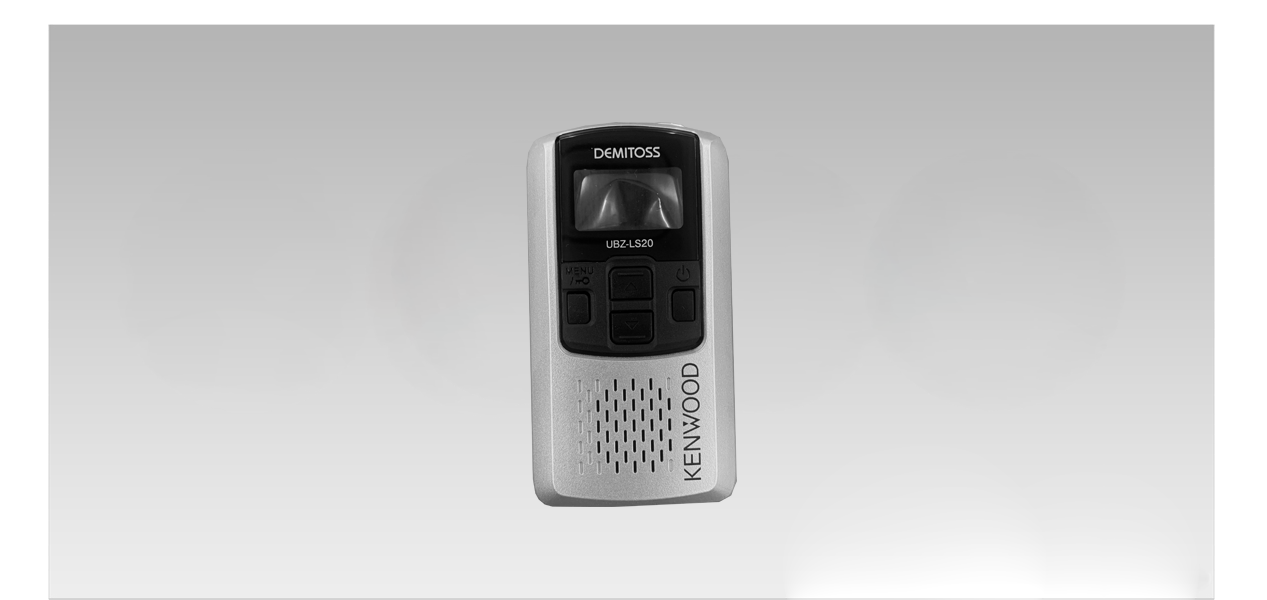

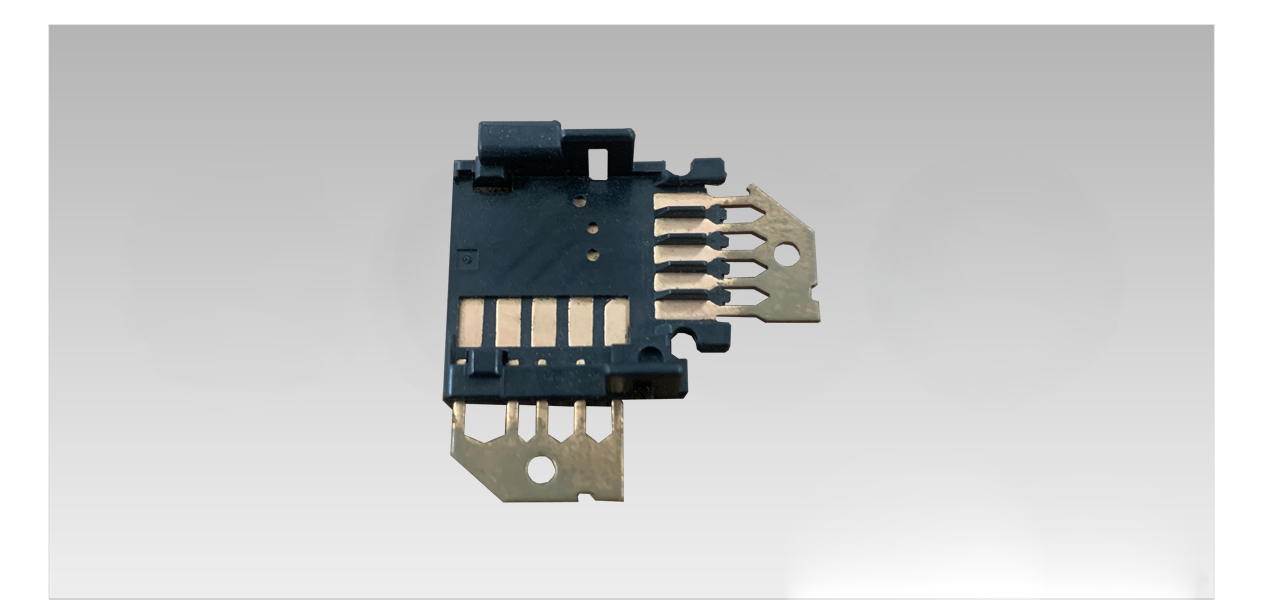

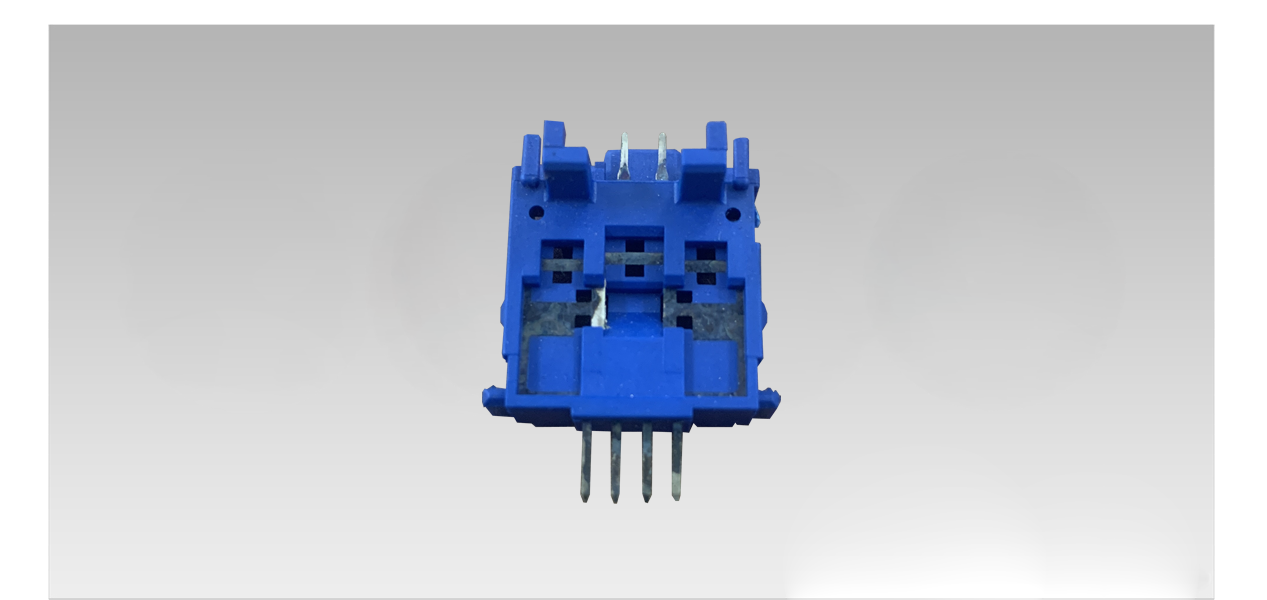

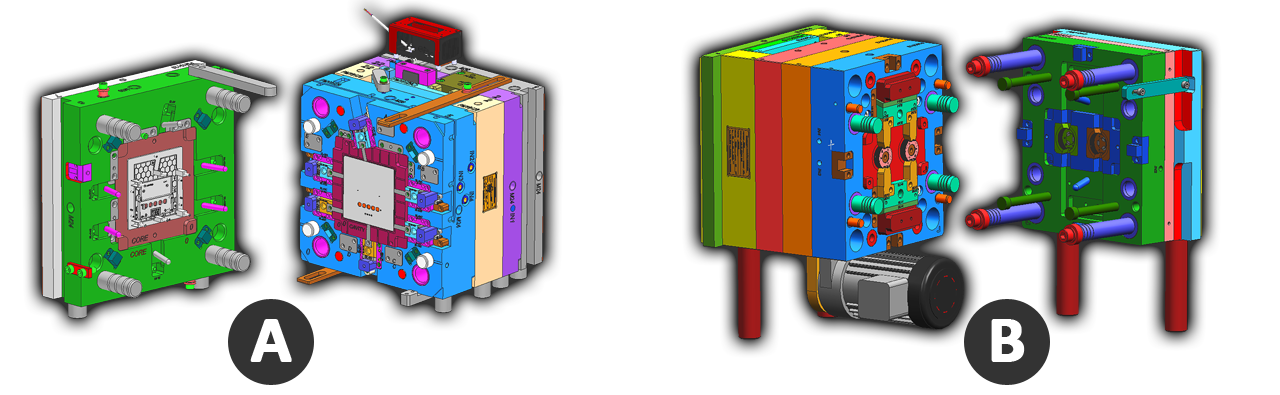

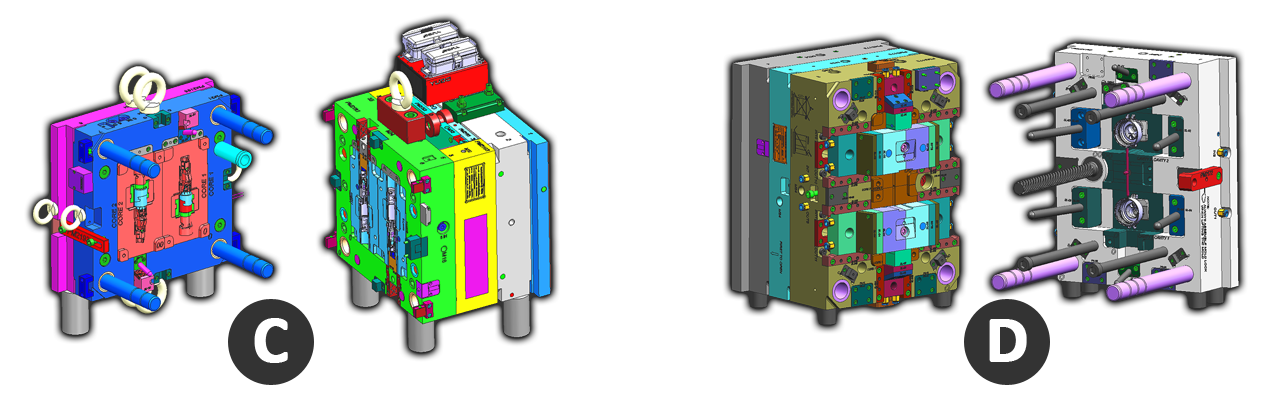

Part of POLARIS capacity is the technical staff composed of open-minded individuals with vast experience in the plastic injection industry, the most having more than 30 years of applied experience. We were able to upgrade this experience by infusing adaptations from the latest technology available. This learnings enabled us to successfully handle not only the basic but also very complicated projects (Such as molds with difficult structures using different peripherals as shown below):

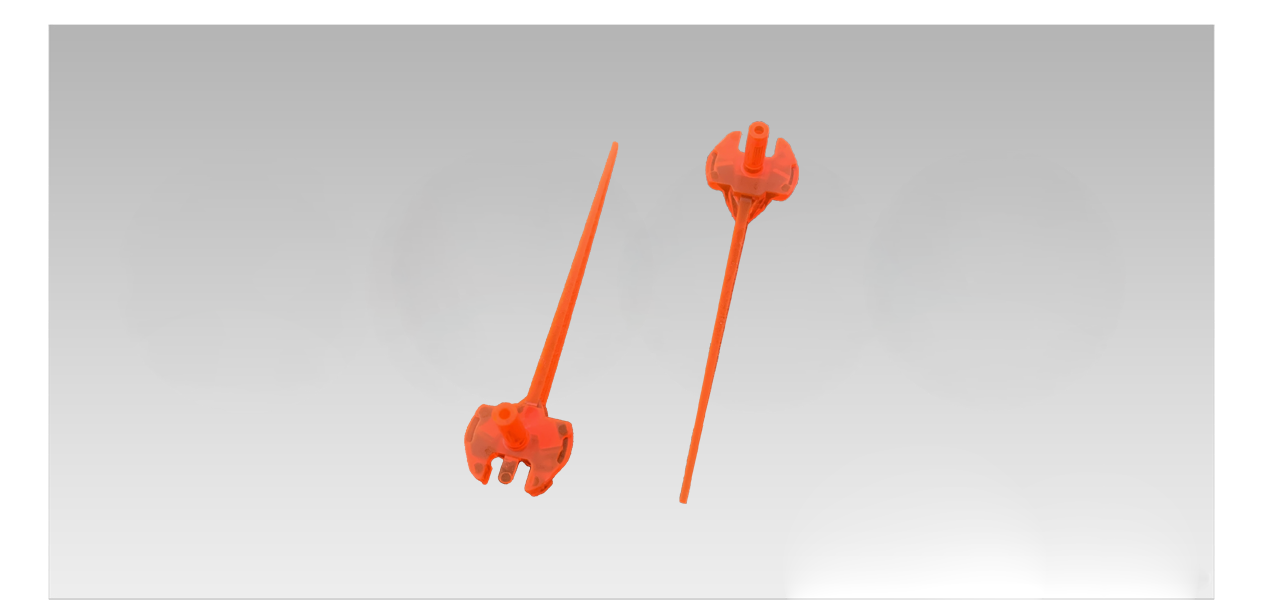

(A) Molds with reversed cavity ejection system using mechanical link. This mold also has hot runner system and multiple sliding cores.

(B) Molds with servo rack motor, combination gears, and multiple slider.

(C) Molds with reversed cavity ejection using hydraulic system. it is also equipped with hot runner system that has sequence-controlled gate valve, plate sequence locks that control the movement of core slider, and multiple sliding cores and angle lifters.

(D) Molds without ejector system but with mechanical gearings to control the ejection and release of the threaded area of plastic part.